- The office building was capped on April 2, 2025.

- The shelf production base has started construction.

- How to wholesale and purchase heavy-duty beam racks

- Purchase methods for heavy - duty warehouse racks

- How to arrange heavy - duty beam racks

Contact person:Mr. Huang

phone:+86 19579563189

phone:0795-7367888

Email:3498282263@qq.com

Address:No. 6, Wangjin Road, Metal Furniture Industrial Park, Zhangshu City, Jiangxi Province

Purchase methods for heavy - duty warehouse racks

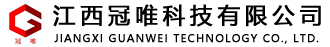

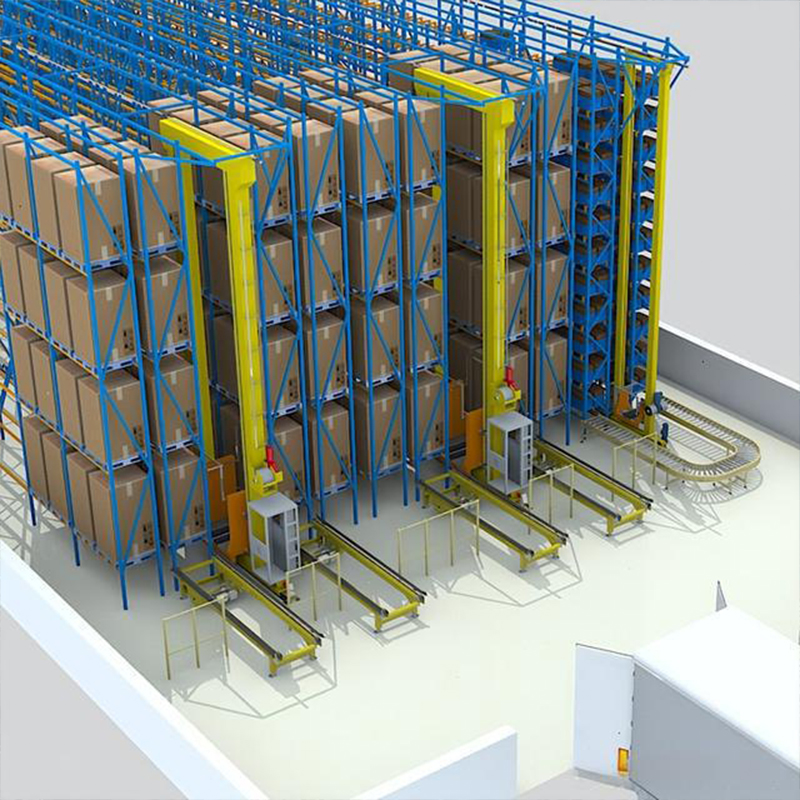

Heavy - duty warehouse racks are widely used in warehouses. There are various types such as beam racks, drive - in racks, narrow - aisle racks, etc. They use a fully assembled structure of uprights and cross - beams to bear goods, with a large load - bearing capacity and a 100% picking rate. However, the variety of heavy - duty warehouse rack types undoubtedly brings a lot of inconvenience to users when making purchases. Purchase Tips: 1. Consider the types of goods and loading containers: Heavy - duty warehouse racks are mostly used to store palletized goods for easy forklift access. As a rack manufacturer, we usually need to know the weight of the palletized goods and the height of the goods with the pallet. Besides, we need to know the specific dimensions of the pallet, and then design the length and depth of the racks according to the pallet dimensions. As a purchaser, before choosing the racks, it is necessary to know these dimensions clearly so that the supplier can plan the rack dimensions well. 2. Consider the rack's shipping frequency: Some specific industries may have relatively high requirements for shipping frequency, which is also very important when purchasing and choosing the type of heavy - duty warehouse racks. Different types of racks meet different shipping frequencies. For example, beam racks have a 100% picking rate, but the space utilization rate is average. 3. Consider the handling equipment: Heavy - duty warehouse racks have a heavy layer load and are normally loaded and unloaded by forklifts. Therefore, when purchasing racks, the purchaser needs to inform the rack manufacturer so that the racks can be planned according to the forklift parameters, such as the rack aisles. 4. Consider the load - bearing level of the warehouse floor: This number is very important. If the warehouse floor can only bear 1 ton and the rack can bear 5 tons, the floor will surely sink or deform, and in severe cases, it may even collapse, causing a safety accident. Do not simply consider building high - level racks to save space, but also consider the basic weight of the materials stored on the high - level racks. Component Analysis: 1. Check the rack material: Heavy - duty warehouse racks are basically made of cold - rolled steel. Only by using qualified materials can qualified racks be produced. 2. Check the rack structure: Observe whether the bent parts and joints of the assembled sample racks are even, without obvious gaps. 3. Check the rack surface: Observe the assembled sample racks to see if the surface spray - painting treatment is uniform and has strong adhesion. Examine every part of the entire rack, especially the perforated parts, to see if there are any areas where the spray - painting is missed. 4. Check the rack welding process: Observe whether the welds are even and full, with a fish - scale - like shape being better. Also, check if there are any places where welding is missed.

-

2025-07-15How to arrange heavy - duty beam racks