- The office building was capped on April 2, 2025.

- The shelf production base has started construction.

- How to wholesale and purchase heavy-duty beam racks

- Purchase methods for heavy - duty warehouse racks

- How to arrange heavy - duty beam racks

Contact person:Mr. Huang

phone:+86 19579563189

phone:0795-7367888

Email:3498282263@qq.com

Address:No. 6, Wangjin Road, Metal Furniture Industrial Park, Zhangshu City, Jiangxi Province

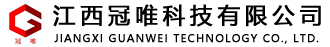

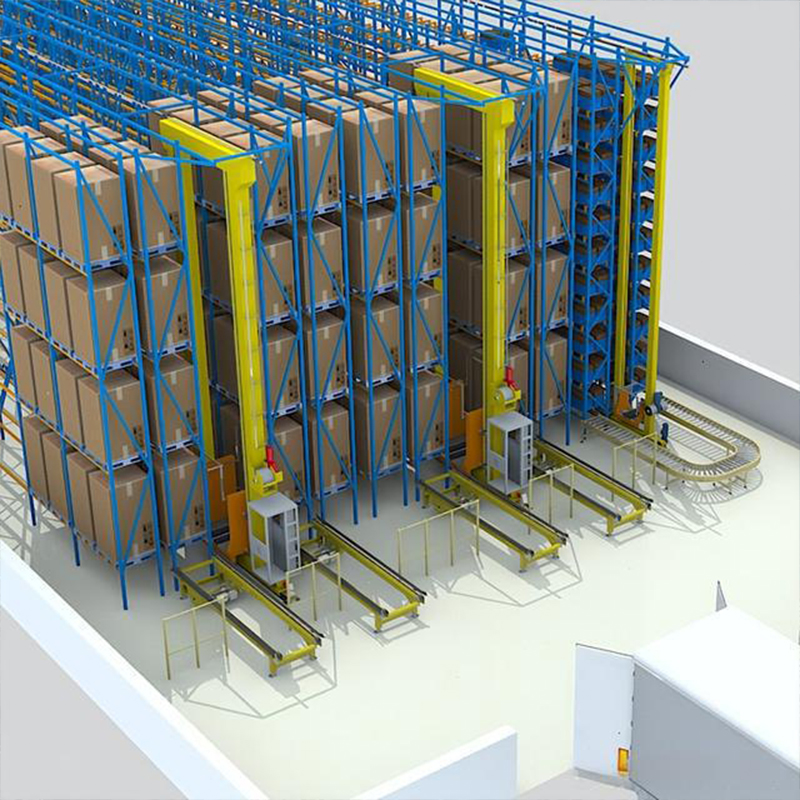

How to wholesale and purchase heavy-duty beam racks

Before choosing heavy-duty beam racks, it is necessary to carry out unitization of containers first. That is, group the packaging and weight characteristics of the goods to determine the type, specification, size of the pallets, as well as the weight per pallet load and stacking height (the weight of goods per pallet is generally within 2000 kg). Then determine the span, depth, and layer spacing of the unit racks accordingly. Decide the height of the racks according to the effective height under the warehouse truss and the maximum fork height of the forklift. The span of unit racks is generally within 4m, the depth is within 1.5m. The height of low and high-position warehouse racks is generally within 12m, and the height of ultra-high-position warehouse racks is generally within 30m (such warehouses are basically automated warehouses, and the total height of the racks is composed of several columns within 12m). Heavy-duty beam racks are suitable for both multi-variety and small-batch items, as well as few-variety and large-batch items, and are mostly used in high-position and ultra-high-position warehouses. Find a professional heavy-duty beam rack manufacturer. Design a professional plan and customize suitable heavy-duty beam racks. The advantage of directly approaching the manufacturer is that the factory-direct price is more favorable. It reduces intermediate links and avoids being marked up by middlemen. Moreover, manufacturers generally have better after-sales service than rack companies and have more guarantees in terms of product quality, so you can use them with confidence. Characteristics of heavy-duty beam racks: 1. The structure of heavy-duty beam racks is simple and reliable, which can be adjusted and combined arbitrarily. The access to the warehouse is not restricted by the sequence of items. It is widely used in the warehousing mode of pallet storage and forklift access. 2. The column slices of heavy-duty beam racks are composed of uprights, horizontal braces, and diagonal braces connected by bolts. The column slices and C-shaped welded beams are inserted to form the rack frame, which is fixed by safety pins, with a simple and reliable structure. Each layer can be freely adjusted up and down at a pitch of 75mm. 3. The layer load requirements of heavy-duty beam racks can be determined according to the size of the uprights and crossbeams. It has the characteristics of large moment of inertia, strong layer load capacity, and strong impact resistance. The maximum layer load per layer can reach 5000 kg/layer under relative design. 4. The height of a single upright of heavy-duty beam racks can reach 12 meters. The plasticity of pallet racks is very high, and mold racks, mezzanine racks, etc. can be built on the basis of pallet racks. 5. Heavy-duty beam racks can effectively increase the storage height of the warehouse and improve the space utilization rate of the warehouse. They are suitable for storing various types of goods. 6. The appearance of heavy-duty beam racks is safer. To prevent forklift collisions, upright foot guards and anti-collision bars can be added. To make the layer load safer, beam stops, layer boards, mesh crossbeams, and other auxiliary facilities can be installed on the crossbeams.

- Previous:Purchase methods for heavy - duty warehouse racks

- Next:暂无

-

2025-07-15How to arrange heavy - duty beam racks